Concrete is a composite material composed of mainly cement, aggregate (fine aggregate and Coarse aggregate), and water whereas, workability is a property of concrete that signifies much wider properties and qualities of concrete and doesn’t project any one particular meaning. Workability is a parameter, a mix designer is required to specify in the mix design process, with full understanding of the type of work, distance of transport, loss of slump, method of placing, and many other parameters involved. The good workability of concrete is always depending upon the user that how workable concrete he should need.

Definition – it is defined as the property of concrete that determines the amount of useful internal work necessary to produce full compaction. In simple words, workability is, how ease you can mix, transport, place, 100% compact and finish the concrete.

Factors affecting workability

Good workable concrete exhibits very little internal friction between particles. The factors helping concrete to have more lubricating effect to reduce internal friction for ease compaction are

- Water content – Increase in water content results in more workable concrete. At site it is normal practice to increase in water content to increase the workability of concrete which decrease to strength of concrete, therefore to maintain the strength, cement should be added as per the given water cement ratio.

- Mix Proportions – Aggregate-cement ratio influences the workability of concrete to a large extent. The higher the ratio, the leaner will be the concrete. In lean concrete, less quantity of paste is available for ‘lubrication per unit surface area of aggregate’ and hence the workability is reduced.

- Shape of Aggregate – Angular, flaky or elongated aggregate makes the concrete hard and less workable when compared to rounded or cubical shaped aggregate because for the given volume or weight, round or cubical shaped aggregate will have less surface area and voids than the flaky or angular aggregates which requires less cement paste for lubrication. Also, round aggregate has less frictional resistance because of its shape that makes the concrete more workable.

- Size of Aggregate – Bigger size aggregates have lesser surface area; hence less amount of water is required to wet the surface and less paste is required for lubricating the surface to reduce the internal friction. So a given quantity of water, big size aggregate give high workability. The above, of course will be true within certain limits.

- Surface Texture of Aggregate – Smooth aggregate produce more workable concrete due to the fact that the total surface area of smooth aggregate is less than the rough aggregate of same volume.

- Grading of Aggregate – This is one of the factors which will have maximum influence on workability. Well graded aggregate means lesser voids, due to which excess paste is available to provide better lubrication, hence increases the workability.

- Use of Admixtures – Various admixtures have various affects on workability of concrete. Air entrained concrete are more workable because air forms bubbles, on which the aggregate slide past each other increasing the workability. Similarly, the fine glassy pozzolanic materials, Inspite of increasing the surface area, offer better lubricating effects for giving better workability.

Measurement of Workability

As we discussed above, workability is a complex property and provides much more information about concrete. There are many methods to measure the workability but none of these methods are satisfactory for precisely measuring workability. But the tests given below, measure the parameters very close to workability and provide useful information.

1. Slump Test

- Slump test is one of the most commonly used test all over the world. Slump test does not measure workability of concrete, although it gives a measure of consistency. For this test, a mould of dimension

Bottom diameter 200 mm

Top Diameter 100 mm

Height 300 mm

Is used with a steel temping rod of diameter 16 mm and length 600 mm.

- Mould is thoroughly cleaned and filled with fresh concrete in 4 layers, each layer of approximately ¼ of the height of the mould. Each layer is tamped 25 times by the tamping rod taking care to distribute the strokes evenly over the cross section. After the top layer has been rodded, the concrete is struck off level with a trowel and tamping rod. Now the mould is taken out immediately by raising it slowly in vertical direction. It allows the concrete to subside and the subsidence is called as SLUMP of concrete. The slump is measured by determining the difference between the height of the mould and that of the highest point of the specimen being tested. Slump is measured in millimeters.

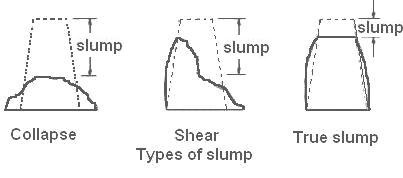

- The pattern of the slump indicates the characteristics of concrete in addition to the slump value. Pattern of the slumps are following: True slump, shear slump and collapse slump are the three types of slumps that may occur in slumps test

True slump – refers to general drop of the concrete mass evenly all around without disintegration.

Shear Slump – implies that the concrete mix is deficient in cohesion and undesirable for durability of concrete.

Collapse Slump – indicates that the mix is too wet and the mix to be harsh and lean.

2. Compaction Factor Test

- This test is more accurate than slump test and in this test the degree of workability of concrete is measured in terms of internal energy required to compact the concrete thoroughly. This test is particularly useful for concrete mixes of very low workability as are normally used when concrete us to be compacted by vibration.

- To perform this test, fresh concrete is placed gently in the upper hopper and the trap door at the bottom of upper hopper is open to allow the concrete to fall in the lower hopper. After the concrete comes in rest in the second hopper, then the trap door of the second hopper is opened and the concrete is allowed to fall into the cylinder.

- Now the weight of the concrete in the cylinder is then determined, which is represented as the weight of partially compacted concrete. Cylinder is refilled with same concrete in layer of approximately 50 mm deep. The layer being heavily tamped or vibrated so as to obtain full compaction. Now this mass of concrete in the cylinder should be measured and it is known as the weight of fully compacted concrete.

- Compaction factor is defined as

C.F. = weight of partially compacted concrete/weight of fully compacted concrete

3. Vee Bee Consistometer Test

- This is a good laboratory test to measure the workability of concrete indirectly. This test determines the time required for transforming a concrete specimen of a conical shape into the cylinder by vibration.

- This test is carried out in such a manner that the specimen concrete in the test receives more or less same treatment in respect of the method of placing as it would in actual execution of the work. This test is preferred for finding workability of stiff concrete mix having very low workability.

- Apparatus consists of a vibrator table resting upon the elastic supports, a metal pot, a slump cone and a tamping rod.

- Slump test is performed in the cylindrical pot of the consistometer. Cone is then lifted up and the slump is noted on the graduated rod by lowering the glass disc on top of the concrete cone. Now the glass disk is placed on concrete and the electrical vibrator is switched on and simultaneously a stop watch started. The vibration is continued till the conical shape of concrete disappears and the concrete assumes a cylindrical shape and the time taken for this is noted as Vee-Bee degree.

Flow Table Test

- This is a laboratory test, which gives an indication of the quality of concrete with respect to consistency, cohesiveness and the proneness to segregation.

- In this test concrete sample is taken in the mould, after removal the mould, vibrate the table by 12.5 mm raise and fall ( 15 times in 15 sec). concrete will spread irregularly on the table. Measure at least six diameter of the spread concrete and evaluate flow percentage.

Flow % = (average diameter of spread -25)/25) x 100

- More flow percentage means more workable is the concrete.