Stress-Strain Curve is a characteristic property of material and does not depend upon dimension of particular specimen used. So Stress-Strain curve is used to study the property of material but not load deflection curve.

Tensile test of mild steel in standardized by ASTM (American society of testing and material) and test is conducted on UTM (universal testing machine), in which solid cylindrical mild steel specimen is used, which have 2 inch gauge length and 0.5 inch gauge diameter on which load is applied gradually (0 to P).

Deflection is produced which can be reported by extensometer (that mean strain can be measured which is the cause of stress). That’s why strain plotted in x-axis and stress plotted in y-axis (so strain is more fundamental and more basic than stress).

Where,

A – Proportional limit point, OA is static/straight line and slope is constant called as young’s modulus (E).

B – Elastic limit point, the portion AB is non-linear.

C’ – Upper yield point (it is recorded in mild steel only).

C – Lower yield point or actual yield point.

CD – Plastic zone and it is called as yield plateau.

DE – Strain Hardening Zone

E – Ultimate point, the stress corresponding to E is called ultimate stress (σu) and stress corresponding to C is called yield stress (σy).

F – Fracture point where metal breaks. The stress corresponding to F is called fracture strength.

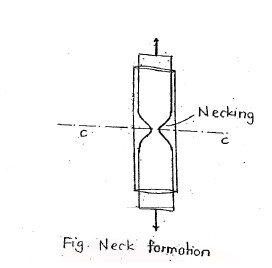

EF – Necking region

Proportional Limit Point

Up to this point stress is directly proportional to strain, that means hook’s law is applied.

Most of the metal have straight line up to proportional limit point except concrete and grey cast iron (that will show slightly curve but for designing purpose assume straight line).

Elastic Limit Point

It is the maximum stress point up to which the material act elastically.

Beyond point A strain increases more rapidly as compare to stress.

In region A to B stress is not proportional to strain.

But for practical purposes designing is done up to point B (A and B are very close to each other).

Upper and Lower Yield Point

Lower yield point (it is actual yield point which explain the load require to maintain yield) is the true characteristic of the material and it is used as a design stress.

Upper yield point (load reaches just before yield start) does not have constant value and it is changed by speed of testing machine.

Difference in upper and lower yield point or fall of stress from C’ to C is due to slipping of carbon atom in molecular structure of steel.

Yield Plateau Region (Yielding)

In this region some strain is developed in the material without increasing the load.

Strain Hardening region

After undergoing large strain that occurs during yielding in region C to D, the steel begins to strain hardrent.

That means in this region, there is regain of strength because of strain (deformation).

That mean in ductile material provide sufficient amount of deformation, strength will increase.

So once point D is reached, material is so hard that for further deformation, higher load is needed. So curve moving upward from D to E.

Strain Softening Region

At point E, necking will start (due to local instability, visible cross-sectional area decrease). After this point, strength will decrease and strain softening will start.

That mean due to necking lower loads are sufficient to keep the further deformation until finally rupture will occur.

At point F, when rupture occur (occurs at 450), failure is cup and cone type.

By increasing temperature yield point get decreases (because by increasing temperature, young’s modulus decreases).

Static load does not affect the property of material, but due to dynamic load property may change.

NOTE –

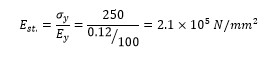

In mild Steel, points A, B, C are close to each other, however C > B > A i.e. mild steel may be called linear elastic metal. Thus elastic and yield stress are taken equal (σe = σy = 250 N/sq.mm).

The elastic strain is close to yield strain which is equal, Ey = 0.12%

The slope of OA is constant which is equal to