Bricks are one of the oldest building materials and are extensively used because of their durability, reliability, strength, low cost, easy availability, etc. in this article, complete brick notes are provided which are very much helpful in all your exams and also for the quick revision.

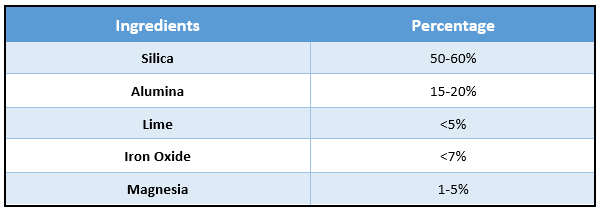

Composition of good red brick

Silica –

> It imparts strength, durability and uniform shape to bricks.

It prevents cracking and shrinking of earth brick.

Excess of silica destroy the cohesion between particles and the bricks become brittle.

Alumina –

It is the chief constituent of every kind of clay. It absorbs water and imparts plasticity to the earth such that it can be moulded.

If alumina is present in excess it causes cracks in bricks on drying and becomes too hard when burnt.

Lime –

It causes silica and alumina to melt on burning and helps to bind them.

It also prevents shrinkage on drying.

Excess lime causes the brick to warp and hence brick loses its shape (unsoundness).

Magnesia –

A small quantity of magnesia in brick imparts a yellow colour to brick and decreases the shrinkage.

Excess magnesia leads to the decay of bricks (unsoundness)

Iron oxide –

It gives red colour on burning when excess oxygen is available and gives dark brown or even black colour when oxygen available is sufficient. If excess of iron present then colour of brick may be dark blue.

It lowers the fusion point of the clay, especially if present as ferrous oxide.

It also gives strength, hardness and im-permeability.

Harmful Ingredients in brick

Lime – when lime is present in lumps it absorbs moisture, it swells and cause disintegration of brick, hence lime should be present in fine powder form.

Sulphur – Excess Sulphur causes decay of brick (unsoundness) and if insufficient time is given (during burning) for oxidation of carbon and Sulphur, then Sulphur will cause the formation of a spongy, swollen structure in the brick and the brick will be decoloured by white blotches.

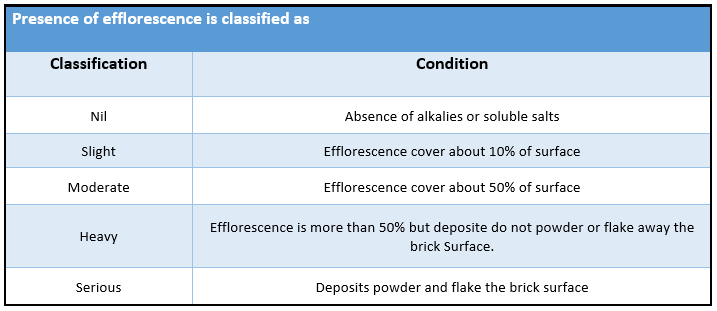

Alkalies – Excess of alkali causes Efflorescence. When bricks come in contact with moisture, water is absorbed and the alkalies crystallise. On drying, the moisture evaporates leaving behind grey or white powder deposite on the brick and this phenomenon is called as Efflorescence. Alkalies are mainly in the form of soda and potash.

Organic Matter – At the time of burning of bricks, organic matter gets burnt completely and leaves behind pores and hence make bricks porous.

Pebbles and Gravels – presence of this impurity does not allow clay to be mixed uniformly which will result in weak and porous bricks and also these types of bricks will not break regularly as desired.

Iron Pyrites (FeS2) – if iron pyrites are present in brick earth, bricks are crystallised and brick may split into two pieces.

Test of Bricks

Generally following tests are to be done on bricks to find out their suitability for the construction work

1. Compressive Strength Test/Crushing strength test (IS:3495-Part I)

- Brick is tested for compressive strength in compressive machine where it is subjected to large compressive stresses.

- As per IS-1077-1976, the minimum compressive strength of brick should be 3.5 N/sq.mm (35 kgf/sq.cm)

- Brick is immersed in water for 24 hours. The frog of the brick is filled flush with 1:3 cement mortar and the specimen is stored in damp gunny bag for 24 hours and then immersed in clean water for 24 hours. The specimen is placed in compression testing machine with 6 mm plywood on top and bottom of it to get uniform load on the specimen. Then load is applied axially at a uniform rate of 14 N/sq.mm and maximum load at which bricks fails is recorded. Then the compressive strength is the ratio of maximum load at failure to the loaded area of brick. Average of five specimen is taken as the crushing strength.

2. Water Absorption test (IS:3495-Part III)

- Water absorption of the brick is depends on their porosity and all the bricks absorb water by capillary action.

- Bricks should not absorb more than 20% of water by weight if immersed in water for 24 hours.

- In this test, bricks are weighed dry first and then they are immersed in water for a period of 24 hours. After that the bricks are taken out, wiped by cloth and weighted wet. The difference in weight indicate the absorbed water.

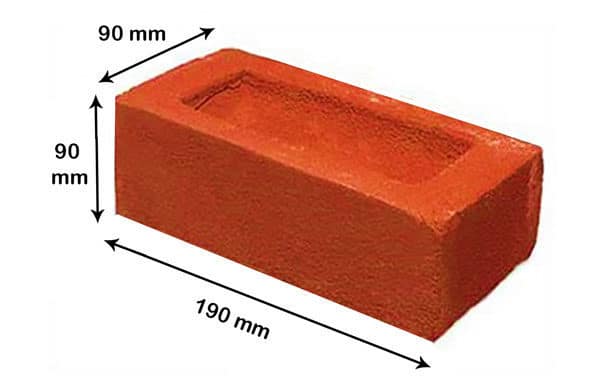

3. Dimension/Shape and size test

- Bricks should be uniform in shape and edges should be truly rectangular with pointed edges.

- As per IS 1077, standard dimension of bricks should be 19 cm x 9 cm x 9 cm.

- For dimension test, 20 bricks are selected randomly and stacked along the length.

IS code permits the following limits

Lengthwise = 368 to 392 cm

Widthwise = 174 to 186 cm

Heightwise = 174 to 186 cm

4. Efflorescence Test (IS:3495 Part III)

- As we see in the harmful ingredients, alkalies causes efflorescence which is not desirable. Hence this test is performed to determine the percentage of efflorescence.

- In this test, bricks are kept in a 150 mm diameter glass or porcelain dish containing water to depth of 25 mm at normal temperature till the water is absorbed or evaporated. Again, water added for a depth of 25 mm. after second evaporation, bricks are examined and measured for white/grey patches.

Properties of Good Bricks

- Physical – Bricks should be table-moulded, well burnt, uniform in shape, colour and texture and with sharp and square edges having standard size as per codes.

- Soundness – When 2 bricks struck together, it must produce clear metallic sound.

- Hardness – The bricks should not show any sign of abrasion when scratched with finger nails.

- Toughness – The bricks should not break when drop on a hard surface from the height of 1 m.

- Water absorption – should not be more than 20% by weight after immersing the brick for 24 hours in water.

- Strength – the minimum compressive strength of brick should be 3.5 N/sq.mm and for good brick compressive strength should be greater than 5.5 N/sq.mm

Classification of Bricks

1. Based on Quality

First Class Bricks

- These bricks are table moulded, standard size and shape, burnt in kiln, uniform texture and have all the qualities of good bricks

- Compressive strength should be greater than 10 N/sq.mm

- Water absorption should be in between 12 to 20% of its dry weight when immersed in water for 24 hours.

- Uses – these bricks are recommended for superior work of permanent nature, also for pointing exposed face work in masonry structure, flooring and reinforced brick work.

Second Class Bricks

- These bricks are ground moulded, burnt in kiln, surface of brick is somewhat rough and shape is slightly irregular and surface have hairline cracks

- Compressive strength should be greater than or equal to 7 N/sq.mm

- Water absorption = 22% of dry weight is allowed.

- Uses – For all unimportant hidden masonry with coat of plaster.

Third Class Bricks

- These bricks are ground moulded, burnt in clamps, have rough surface, not hard, give dull sound when stuck together.

- Compressive strength should be less than 7 N/sq.mm

- Water absorption = 25% of dry weight is allowed.

- Uses – for unimportant and temporary structures and at places where rainfall is not heavy.

Fourth Blass Bricks (Zamma Bricks)

- These are the overburnt bricks with irregular shape and dark colour.

- Uses – used as aggregate for concrete in concrete, road because of the fact that these bricks have a compact structure and hence they are sometimes found to be stronger than even first-class bricks.

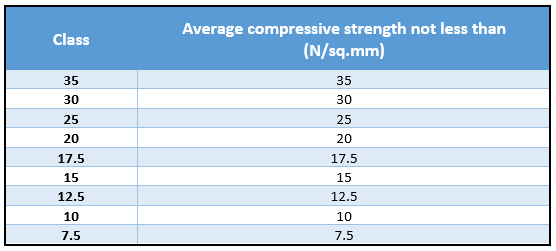

2. Based on Strength

On the basis of compressive strength, Bureau of Indian Standard (BIS) classified bricks as follows: