Strength of concrete is its resistance against rupture. It is represented by compressive strength expressed in MPa or N/sq.mm. Strength may be measured in number of ways, such as strength in compression, in tension, in shear or in flexure.

Quality or grade of concrete is designated in terms of a numbers, which denotes it characteristic compressive strength. Characteristic strength is defined as strength of concrete below which not more than 5% results are expected to fall.

Till date no relation exists between compressive, tensile, bending and shear strengths of concrete. But it is observed that the tensile and bending strength of concrete are 10 and 15 percent, respectively of the compressive strength of concrete and shear is approximately 20% of the uniaxial compressive strength.

Since the strength of concrete is related to the structure of hardened cement matrix, it assumes more importance. So, for assessing the strength of concrete, codes specify compressive strength test and tensile strength test.

1. Compressive Strength Test

Compressive strength test is the most common test conducted on hardened concrete, partly because it is an easy test to perform, and partly because most of the desirable characteristic properties of the concrete are qualitatively related to its compressive strength.

There are two types of moulds or specimens, through which the compressive strength test can be performed. One type is Cube mould of size 150 x 150 x150 mm and another type is cylindrical having diameter 150mm and length 300 mm. largest nominal size of the aggregate does not exceed 20 mm.

In moulds, the mixed concrete is filled in layers of 50 mm and each layer is tamped with bar of 10 mm diameter and 600 mm long, 35 times.

Now the test specimens are stored at a temperature of around 27±30C at 90% humidity for 24 hours from the time of addition of water to the dry ingredients. After this, specimens are removed from the moulds and immersed in water, for curing up to desired days.

Usually, specimens are tested for 7 days or 28 days strength but standard codes only suggest 28 days strength only.

Now the specimens are tested for its compressive strength in universal testing machine (UTM) by applying gradual load of 14 N/mm2/minute until the specimen fails. Average of the three values is taken as the compressive strength of concrete, provided the individual variation is not more than ±15% of the average.

Note –

- The strength of cylindrical mould nearly comes out 0.8 times the strength of cubical mould.

- Codes also recommends use of cubes of size 100x100x100 mm provided the aggregate size does not exceed 19 mm.

2. Tensile Strength Test

Concrete as we know is relatively strong in compression and weak in tension. In reinforced concrete members, little dependence is placed on the tensile strength of concrete since steel reinforcing bars are provided to resist all tensile forces. However, tensile stresses are developed in concrete due to drying shrinkage, rusting of steel reinforcement, temperature gradients and many other reasons. Therefore, the knowledge of tensile strength of concrete is of importance.

Direct measurement of tensile strength of concrete is difficult. Neither specimens nor testing apparatus have been designed which assume distribution of the “pull” applied to the concrete.

a. Flexural tensile strength test

- It is an indirect test for measuring the tensile strength of concrete. This test is done to determine the tensile load at which concrete may crack.

- In this test, concrete is filled in the mould of size 150x150x700 mm and compacted with the tamping bar weighing 2 kg, 400 mm long and have a ramming face 25 mm square.

- Specimen is placed in the testing machine on two 38 mm diameter roller with a centre to centre spacing of 600 mm. then the load is applied through two similar rollers mounted at the spacing of 200 mm c/c.

- Load is applied without shock with increasing the load continuously at a rate of 0.7 mm/min/mm2 until the specimen fails.

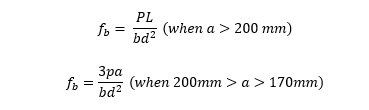

- The flexural strength of the specimen is expressed as the Modulus of rupture (fb),

Where,

a = distance between the line of fracture and the nearest support,

b = width of specimen

d = depth of specimen at the point of failure

L = length of the span on which the specimen is supported

P = maximum load in kg applied to the specimen

Note –

- IS code also recommending use of specimen of size 100x100x500 mm provided the largest nominal size of aggregate does not exceed 19 mm.

b. Split Tensile Strength Test

- As its practically very difficult to apply uniaxial tensile load, therefore few indirect methods are developed to determine tensile strength.

- In split tensile strength test a compressive force is applied to the specimen such that specimen fails due to induced tensile stress.

- Cylindrical specimen is used having diameter not less than 150 mm or 4 times the maximum size of coarse aggregate. Length of cylinder varies from one to two diameters.

- The test is carried out by placing this cylindrical specimen horizontally between the loading surfaces of a compression testing machine and the load is applied until failure of the cylinder at a rate as to produce a tensile splitting stress of about 2.0 N/sq.mm/minute.

- Specimen fails finally by splitting along the loaded diameter and maximum load applied is recorded.

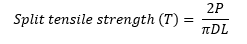

Where,

P = maximum load at failure

D = diameter of specimen

L = length of specimen

Factors Affecting Strength of Concrete

Water Cement Ratio

Compressive strength of the harden concrete is inversely proportional to the w/c ratio (Abram’s Ratio). Water to cement ratio is defined as the weight of water to that of cement in the concrete mix.

Size of Specimen

Most common size of the specimen used is 150 mm cube. It is observed that the strength of cylindrical specimen is 0.8 times of the strength of cube specimen. If the size of the cube is decreases, compressive strength tends to increase in compare to 150 mm cube and vice-versa.

Air Voids

Strength of concrete decreases with the increase in percentage of air voids. Generally, air voids are formed by evaporation of water used for concrete mix and by entrained air.

Age of Cement

As the cement ages, its strength reduces since it gets set by absorption of moisture.

Type and Size of Aggregate

- Rounded, spherical or cubical shaped aggregate when compacted contains less voids than an angular and flaky aggregate of the same nominal size and they give more strength.

- The larger maximum size aggregate gives lower surface area for developments of gel bonds which is responsible for the lower strength of concrete.

- Bigger size aggregate causes a more heterogeneity in the concrete which will prevent the uniform distribution of load when stressed and lowers the compressive strength.

- Large size aggregate is used, due to internal bleeding, the transition zone will become much weaker due to the development of microcracks which results in lower compressive strength.

- It is observed that the high strength concrete gives lower strength as compared to lean concrete if large size aggregate is used.

Cement to Aggregate Ratio

Providing all other factors kept constant, increase in cement aggregate ratio will increase the strength to some extent.

Degree of Compaction

Inadequate compaction leads to increase air void content and results in a loss of strength.