Chain Surveying is the method of surveying of land where only linear measurements are required and no angular measurements are taken.

Chain Surveying is the simplest method of surveying and only used for small ground areas with simple details. It consists of measuring the lengths of the lines marked on the field.

To perform the chain surveying, instrument used is only a chain or a tape with few ranging rods.

Chain surveying is used for marking the boundaries and other details of land for preparation of maps.

Principles of Chain Surveying

In chain surveying, the area to be surveyed is divided into frame work of triangles. The three sides of the triangle viz. AB, BC and CA are measured in the field with the help of chains.

For locating the details, offsets are taken. The plan of the ground and details (taken by offsets) are plotted on the map.

For the survey of large areas, the area is divided into a frame work of triangle. The exact triangles will depend upon the extent and the type of the area to be surveyed. In general, a long base line is run through the traverse.

Chain Surveying Terminologies

Main Survey Stations

These are the prominent points that are connected by survey lines to form triangles. Alternatively, these are the points at the start and end of all the survey lines.

Main Survey Lines

The lines connecting the main survey stations are called as survey lines or main survey lines.

Check lines/Proof lines

The line measured for checking the accuracy of survey work is called check line or proof lines.

- After plotting the plan from the survey lines, the length of the check line is scaled off from the drawing and compared with the measured line in the field. If there is no error then length of the check line measured from the plan should conform to measured value in the field.

Base Line

Base line is the biggest central line which divides the whole area into two parts. The frame work of triangles is built on the base line.

Tie Lines

If the distance of the detail from the chain line is very large, then long offsets need to be taken. Tie lines are the lines that are run to locate details in order to avoid long offsets.

Range Tie

These are the oblique offsets taken along the wall of the building.

Offsets

These are the lateral distances measured from the survey lines in order to locate the details.

- Two types of offsets are there, Perpendicular offsets and oblique offsets.

- Perpendicular offset is perpendicular or normal to the survey line and oblique offset is the short measurement which is inclined to the survey line.

Chainage

It is the distance of a prominent point from the start point.

Chains

Chains are used to measure distances and chain surveying is used where high accuracy is not required in measurement.

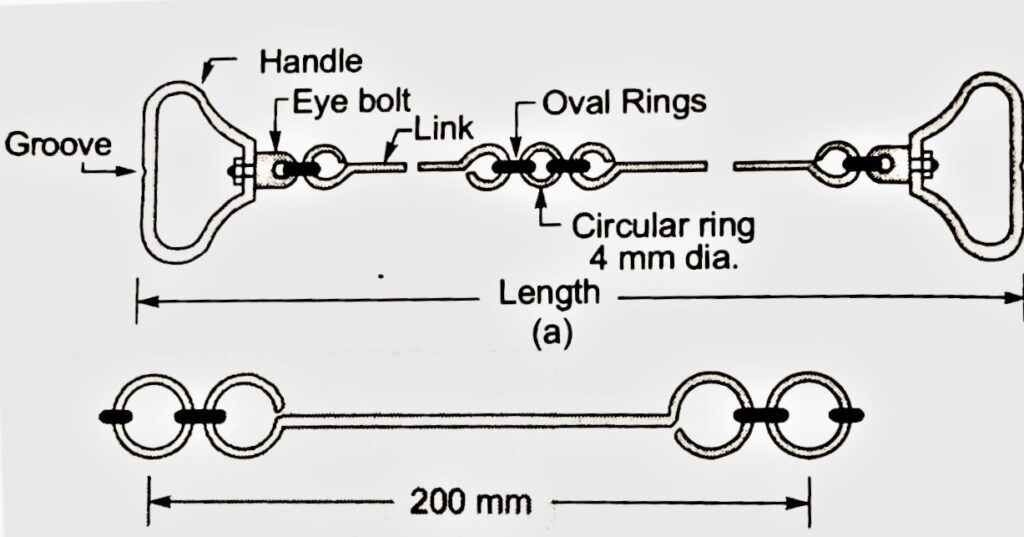

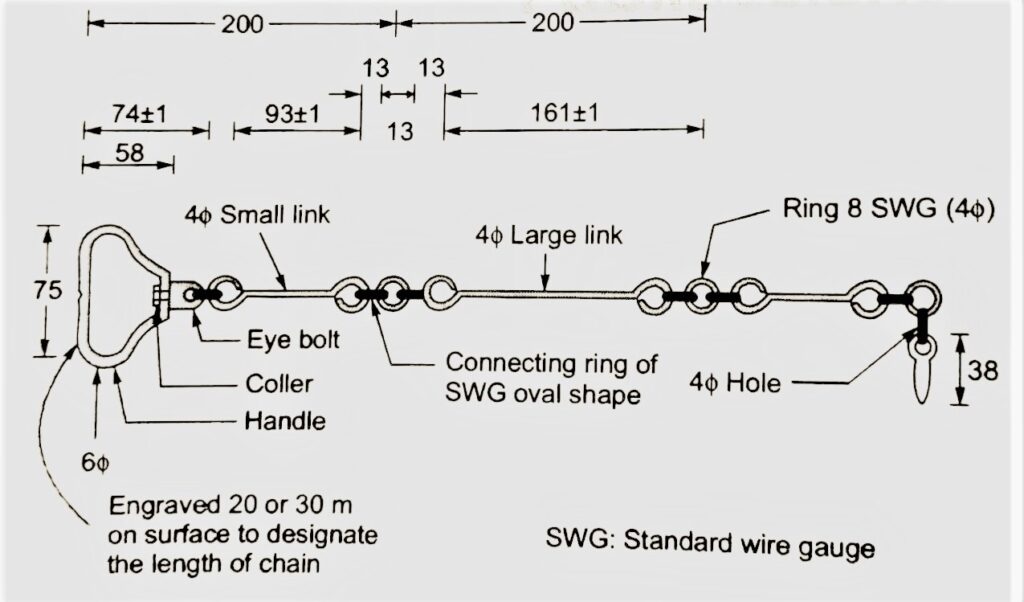

- The chain consists of a number of links made of 4 mm mild steel wire. Each end of a large link is bent a loop and the various loops are connected to each other.

- The connecting link consists of two oval rings at the ends and a circular ring in the middle.

- The two ends of the chain are provided with brass handles which are used to handle the chain and are often used to drag the chain on the surface. These end handles can rotate about the eye bolt without causing twisting of chain and thus gives flexibility to the chain.

- In order to read out the fraction of a chain length, brass tallies or tags or rings are provided at some fixed interval on the chain.

Types of chains

There are numerous types of chain. Some of them are following

1. Metric Chain

As per IS 1492:1970 the surveying chains are of four different lengths

a. 5 m length Chain (25 links)

b. 10 m length Chain (50 links)

c. 20 m length Chain (100 links)

d. 30 m length Chain (150 links)

- For 5 m and 10 m long chains, brass tallies are provided at every 1 m of chain and for 20 m and 30 m long chains, small brass rings are provided at every meter length and tallies are provided at every 5 m length.

- The shape of tallies at 1 m and 4 m are the same. Similarly, for 2 m and 3 m, the shape of tallies are the same since the distance can be measured from either end on the chain.

2. Engineer’s Chain

- Engineer’s chain is 100 feet long and consist of 100 links of 1 feet each.

- At every 10 feet, there is a brass tag of a particular type. The number of notches on the tag indicates the number of 10 segment link.

- The 50 link tag is circular without any notch.

3. Gunter’s chain

- It is also called as surveyor’s chain and is of length 66 feet. It is composed of 100 links of 0.66 feet each.

- This length of 66 feet is most convenient when distances are required to be measured in furlongs or miles as

1 mile = 8 furlongs = 80 Gunter’s chain = 5280 feet

- This length of 66 feet is also convenient when area are to be measured in acres as

1 acre = 4840 sq. yards = 43560 sq. ft = (660)2 ft = (10 Gunter’s Chain)2.

4. Revenue Chain

It is 33 feet long and consist of 16 links of 33/16 feet each.

Advantages of Chain

- A chain is useful for rough measurement.

- Chain can easily be read in the field.

Disadvantages of Chain

- The problem with chain is that it is quite heavy.

- It sags considerably when suspended in air.

- Its length gets changed due to shortening or elongation of links and is thus suitable for low precision work only.

Required Field Work in Chain Surveying

1. Reconnaissance

It is the preliminary inspection of the area to be surveyed in order to have an idea about terrain, main features present on the area to be surveyed, major undulation or depressions in the ground etc. After that, appropriate locations of the main survey stations and survey lines are selected. The inter-visibility of the selected stations is checked after fixing the ranging rods. During reconnaissance, the surveyor makes a rough index sketch of the area showing the principle features like temples, buildings, towers etc.

2. Stations Marking

Next step is to marking of the stations on the ground. The stations are marked by fixing the ranging rods if the soil is soft and also by making the heap of stones in case of hard ground. For extensive survey works, wooden pegs are used to mark the survey stations.

3. Running the survey lines

Survey lines are run on the ground to measure the distance between the main survey stations. At least three persons are required to perform the chain survey. The three persons are a leader, a follower and the one who directs the work and records the measurements. Offsets are required to be taken and chainages of all the important features like drain, roads, fence etc. are recorded down.

Taking the offsets

Offsets are the lateral distances measured from the main survey lines. Offsets are of two types, Perpendicular offsets and Oblique offsets.

The error due to measurement of offset or due to the incorrect direction of offset increases as the length of offset increases. Thus offset should be so selected such that offset distance is as short as possible.